Bambu Lab X1E – Combo

22.999,00 kr. incl. moms

*Kan ikke sendes til pakkeshop

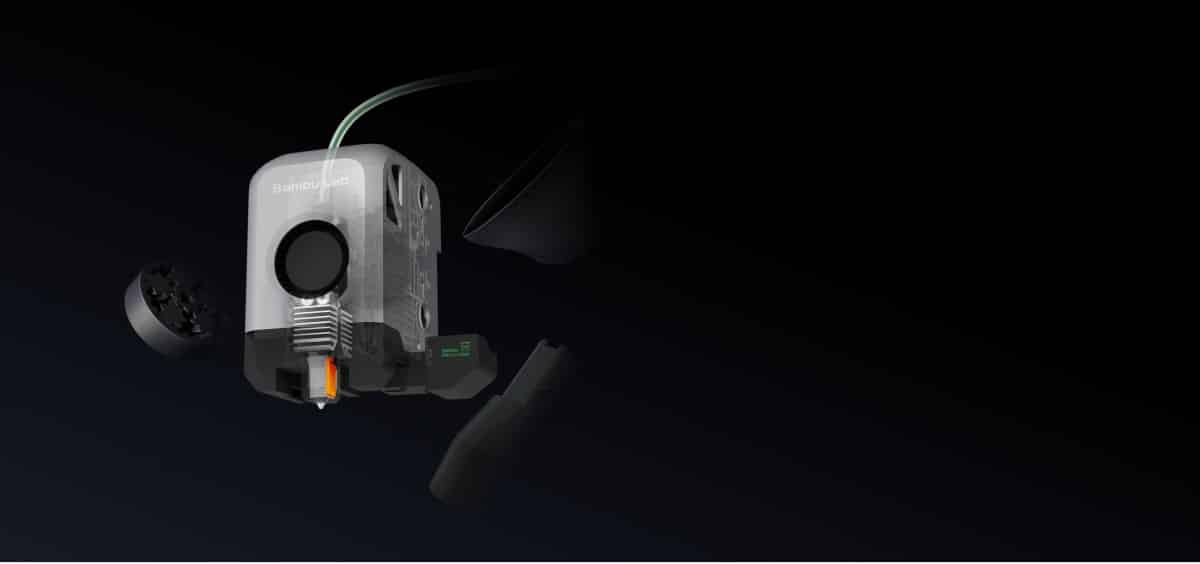

Introducing Bambu Lab X1E 3D Printer – Unleash Precision in Industrial Innovation. Elevate your enterprise with our cutting-edge solution, featuring a higher temperature hotend and a heated build chamber for unparalleled printing capabilities. Experience peace of mind with WPA-2 Enterprise-level WiFi security. The X1E, a refinement of the X1 Carbon Combo, is crafted for industrial leaders who demand excellence. Precision, performance, and security converge in the Bambu Lab X1E – your gateway to advanced 3D printing for the future of industry.

Highlights

- Includes Automatic Material System

- Build Volume 256 x 256 x 256 mm

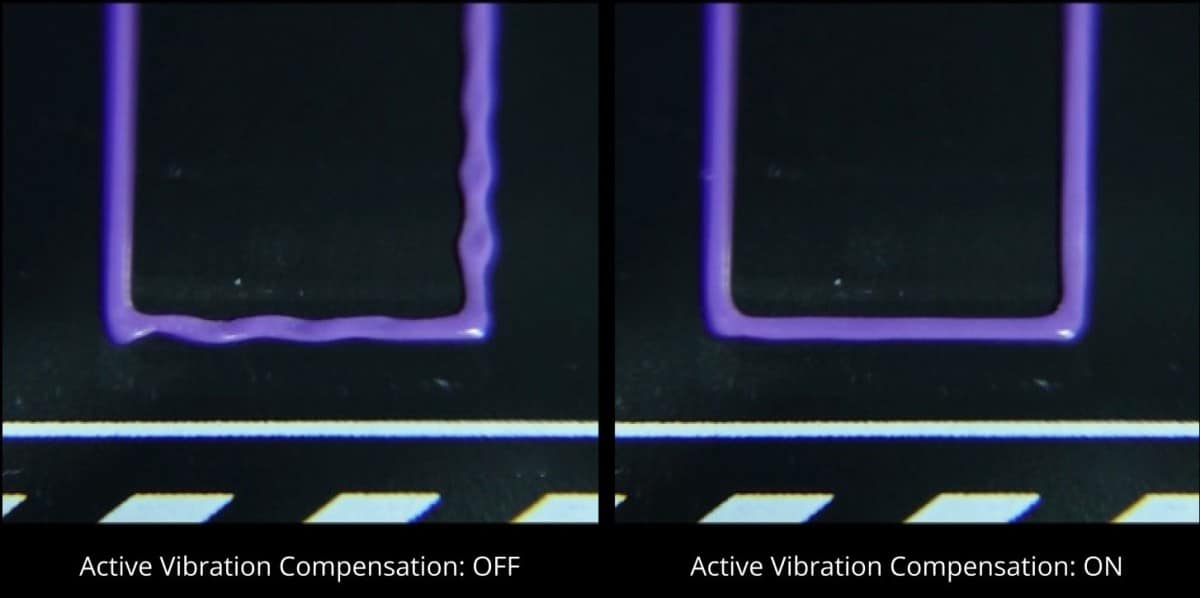

- Max Speed 500 mm/s

- Max Hot End Temperature 320°C

- Enhanced And More Connection Options

Ikke på lager

Fragt fra 49,- fri fragt ved køb over 500,-