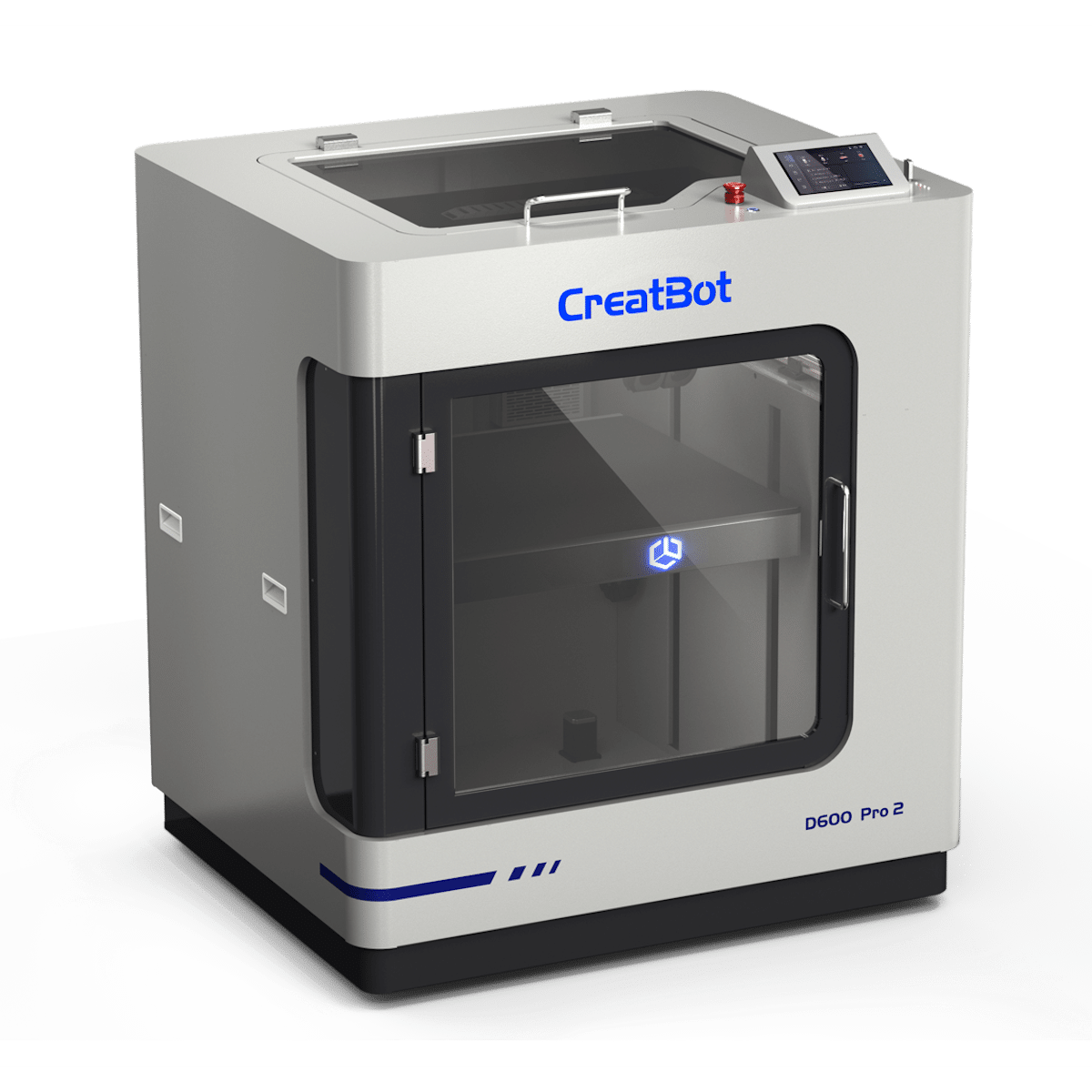

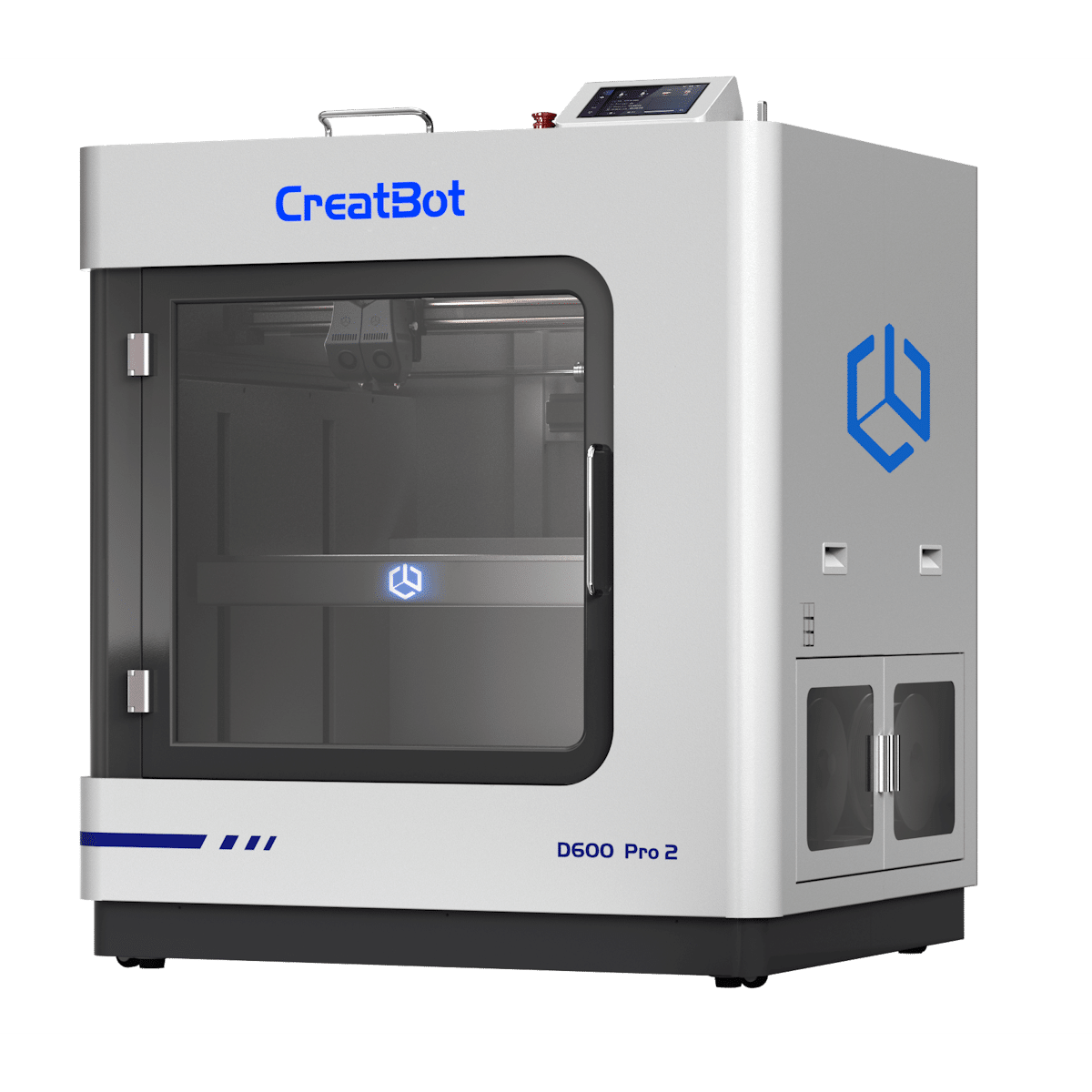

CreatBot D600 Pro 2

122.000,00 kr. incl. moms

D600 Pro 2 is a brand-new product based on D600 Pro that is now being released with more advanced design concepts and deep technical reserves. It has been professionally designed, has powerful performance, and features no shortcomings. Large print volume, faster speed, stronger material compatibility, simpler operating procedures, and more stable 7/24 operation. Undoubtedly, it will capture the needs of all professional 3D printer users within 600mm3 size worldwide.

Highlights

- 600 x 600 x 600 mm

- 420°C+100°C+70°C

- High resolution & speed

- Removable Magnetic Platform

- Reliable 24/7

- Fully enclosed

Ikke på lager

Fragt fra 49,- fri fragt ved køb over 500,-

Beskrivelse

Discover the leading professional large format 3D printer

D600 Pro series has been proven to be the worlds most popular professional large-size 3D printer. It has undergone 6 years of market accumulation and verification. From the beginning of its launch, it has continuously been upgraded and improved based on user needs and feedback. So far, approximately 30 improvements have been made in product details, incorporating new technologies, and fixing issues. A very stable professional large-size 3D printer, deeply prefered by small and medium-sized enterprises.

D600 Pro 2 is a brand-new product based on D600 Pro that is now being released with more advanced design concepts and deep technical reserves. It has been professionally designed, has powerful performance, and features no shortcomings. Large print volume, faster speed, stronger material compatibility, simpler operating procedures, and more stable 7/24 operation. Undoubtedly, it will capture the needs of all professional 3D printer users within 600mm*3 size worldwide.

Auto-rising Dual Extruders 420 ℃

D600 Pro 2 is equiped with new smart auto-rising dual-extruders kit hot-end temperature up to 420 ℃. It is able to print engineering-grade materials like PLA, ABS, PC, UltraPA, carbon fiber, glass fiber, etc with quick remove support materials.

Magnetic suction platform

Exclusive R&D of magnetic platform with large size, easy removable platform, high temperature resistance exceeding 100 °C, long-term use without demagnetization. For oversized models, it is easy to detach them quickly and the bottom of the model is flat. Convenient to all operators.

Powerful core

32-bit motherboard, equipped with a powerful NPU core processor, can quickly respond to any program instructions without delay.

7-inch touch screen

A new UI design language, better user interaction experience, and more convenient operation.

Z magic box: Texture Elimination

For tall Z distance 3D printing devices, the texture of the Z-axis will deteriorate with the model height increases. Our Z-axis magic box technology can greatly reduce or even eliminate the Z-surface texture of tall models, ensuring that the surface quality of the model remains smooth and consistent.

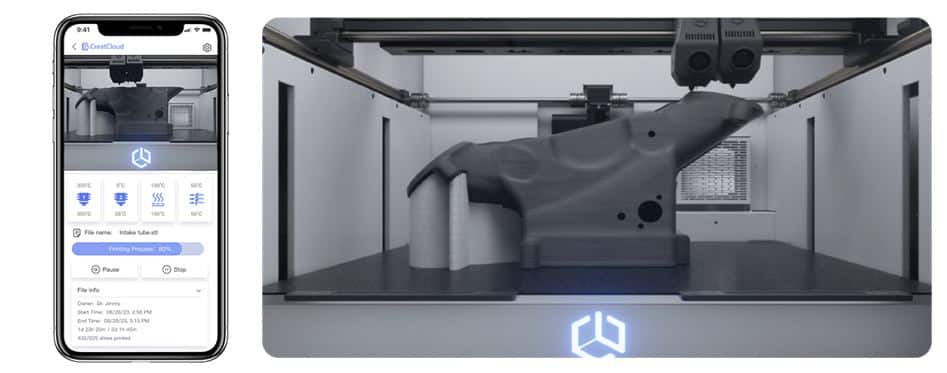

Camera Control Technology

Camera control technology allow customers to control printing process on speed,pause,temp.etc with an APP remotely, which can get best printing quality with shortest time without failure. A very useful feature on large model and long time printing.

| Construction an Technical Details | |

| Usable Nozzle Type | MK8 |

| Usable Filament Diameter | 1.75 mm |

| Max Nozzle Temperature | 420 ºC |

| Open Filament System | Yes |

| Extruder Type | Direct drive |

| Recommended Printing Speed Max | 150 mm/s ( |

| Build Area | 600 mm x 600 mm x 600 mm |

| Dual Build Area | 540 mm x 600 mm x 600 mm |

| Build Plate Temp Max | 100 ºC |

| Build Plate Surface | PEI sheet |

| Build Plate Material | Flexible Steel Plate |

| Build Plate Attachment | magnetic |

| Build Plate Leveling System | mechanical switch |

| Build Chamber During Process | Open or Closed |

| Build Chamber Heated | Yes, max 70°C |

| Filament Chamber Closed | Yes |

| Extruder Number Of | 2 |

| Extruder Construction Type Dual | Dual-head with electronic lifting system |

| Installation Space / Requirements | |

| Total Mass Overall Dimensions | 1080 mm x 920 mm x 1245 mm |

| Total Weight | 200 kg |

| Ambient Operating Temperature | 15°C – 32°C |

| Max Power Consumption | 5500 W |

| Voltage | AC: 220 V240 V (50-60 Hz) |

| Equipment | |

| Emergency Shutdown | Yes |

| Hepa Filter | Yes |

| Filament Runout Sensor | Yes |

| Power Loss Fail Safe | Yes |

| Touch Screen | Yes |

| Camera | Yes |

| Connection | |

| USB Port | Yes |

| WLAN | Yes |

| Accuracy | |

| Layer Height | 0.05 – mm |

| Shipping | |

| Shipping Box | 1150 mm x 1000 mm x 1410 mm |

| Shipping Weight | 245 kg |

Yderligere information

| Vægt | 245 kg |

|---|---|

| Størrelse | 115 × 100 × 141 cm |

| Anbefalede Print hastighed | 150 mm/s |

| Build Volume | 600 x 600 x 600 mm |

| Extruders | 2 |

| Filament Diameter | 1.75 mm |

| Producent | CreatBot |

| Software | CreatWare |

| Type | FDM Printer |