Raise3D E2

29.999,00 kr. incl. moms

På fjernlager, leveringstiden er 3 - 4 hverdage

Fragt fra 49,- fri fragt ved køb over 500,-

Beskrivelse

The New E2 Precise, Reliable and Affordable

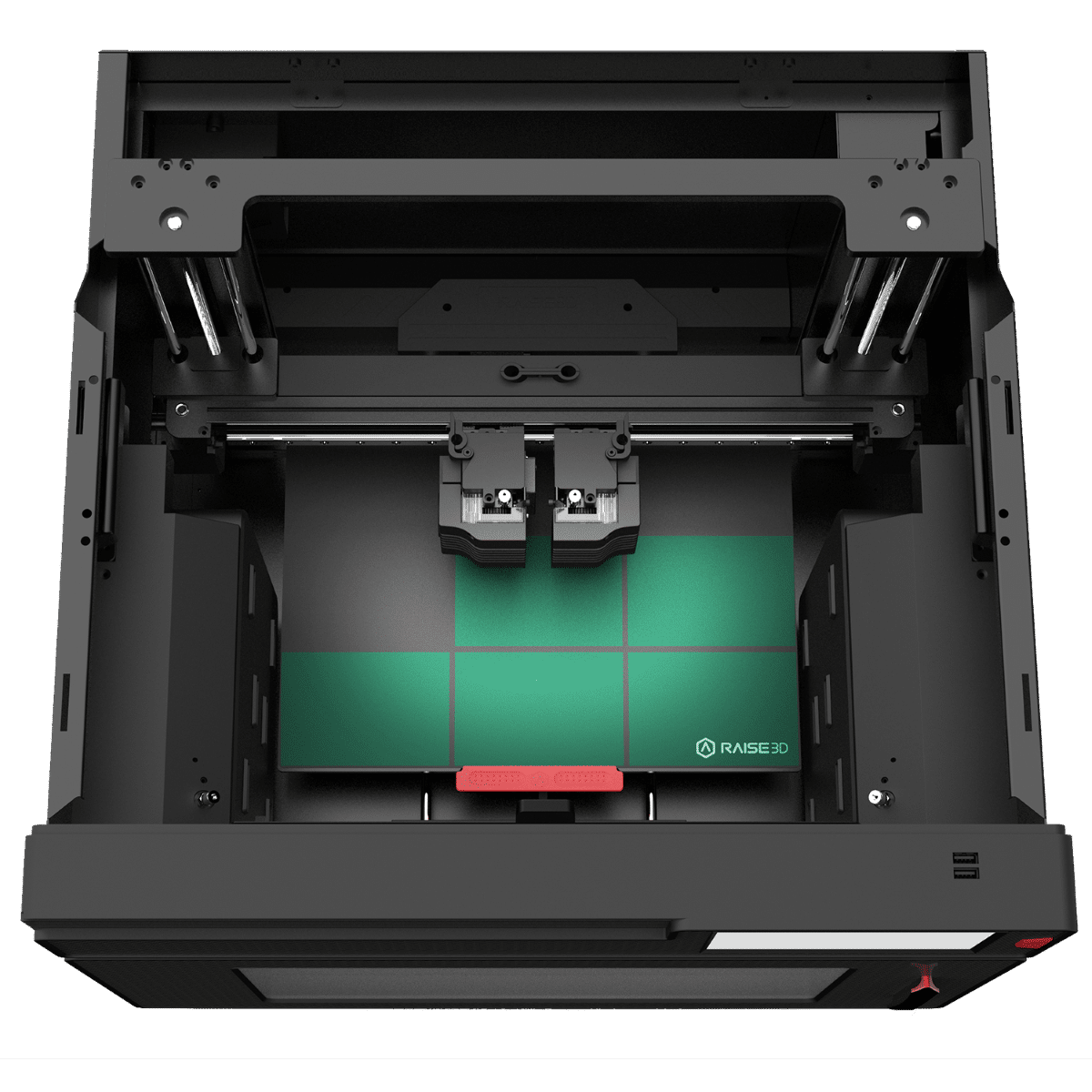

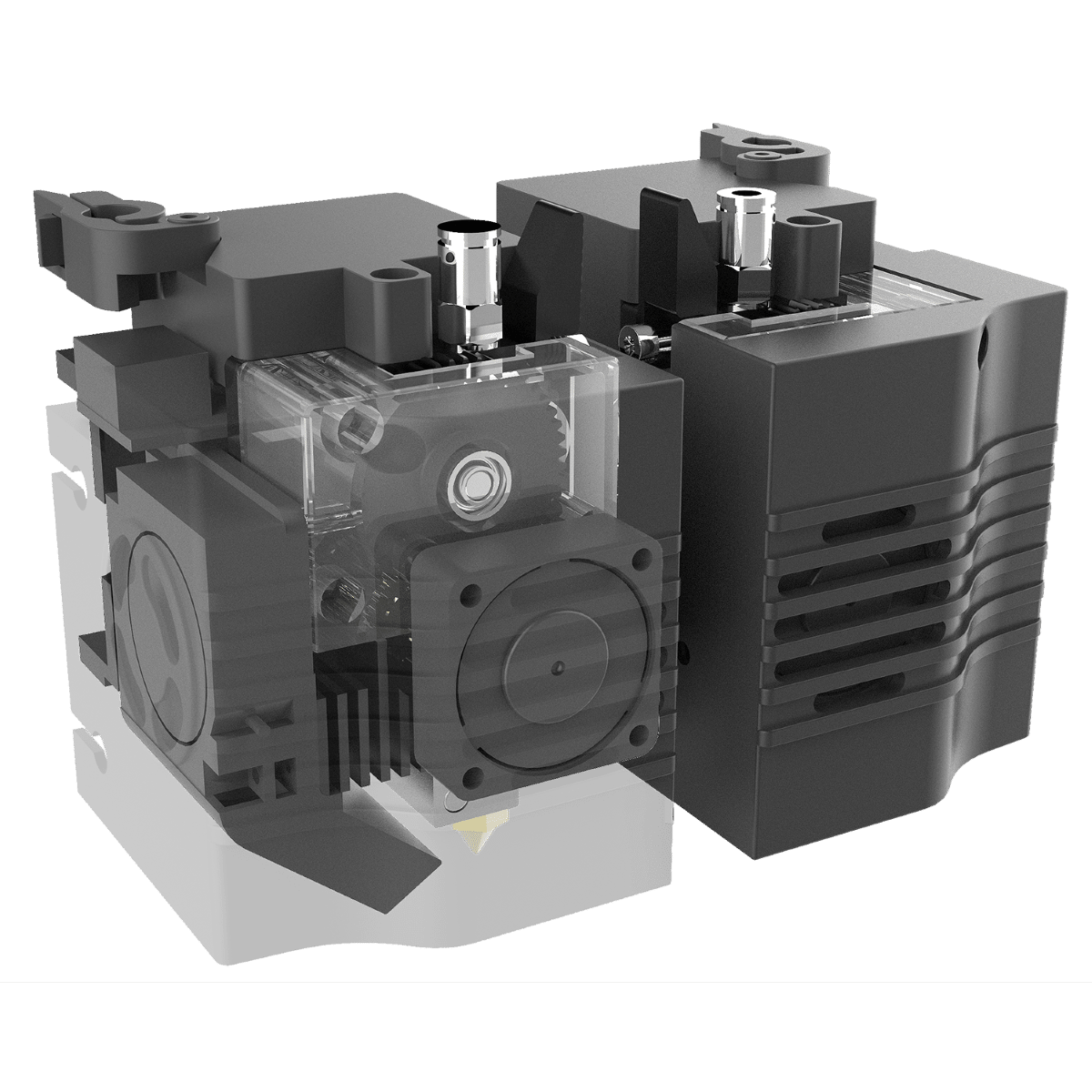

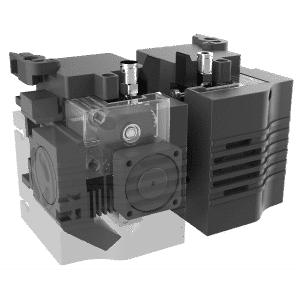

IDEX – Independent Dual Extruders

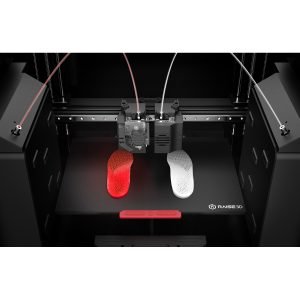

Mirror Mode

Print symmetrical 3D models simultaneously. Greatly increase productivity.

Duplication Mode

Use both extruders in synchronized printing. Doubles production capabilities.

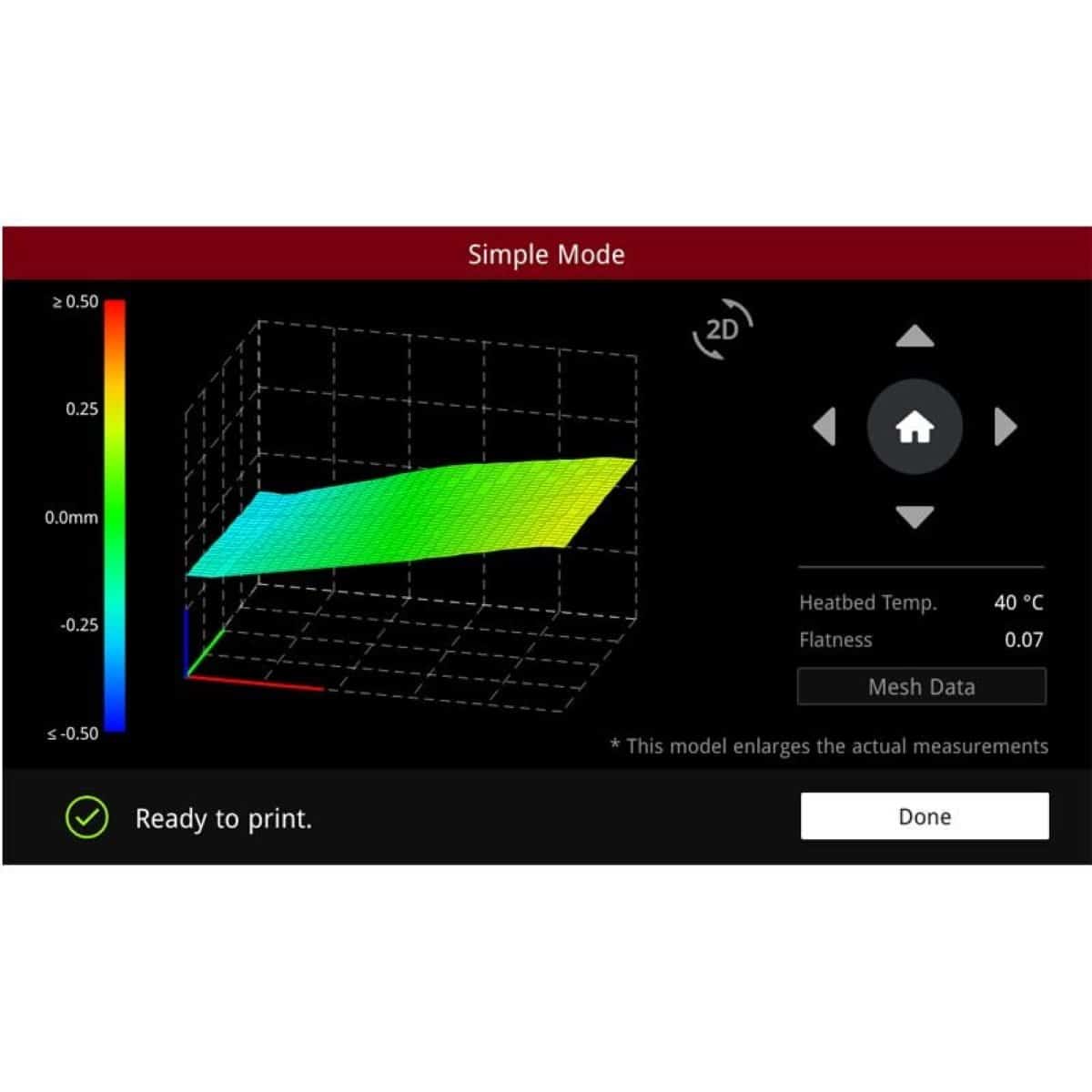

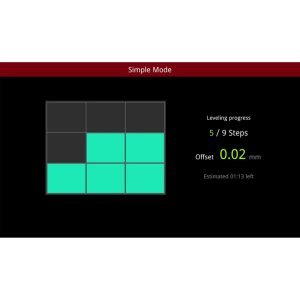

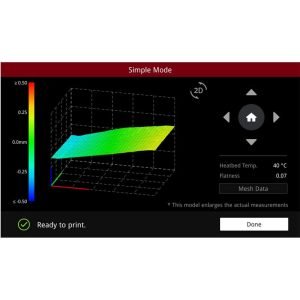

Automatic Bed Leveling

- High precision mechanical probe for automatic flatness detection

- Reduces the need for rafts

- Ensures solid foundations

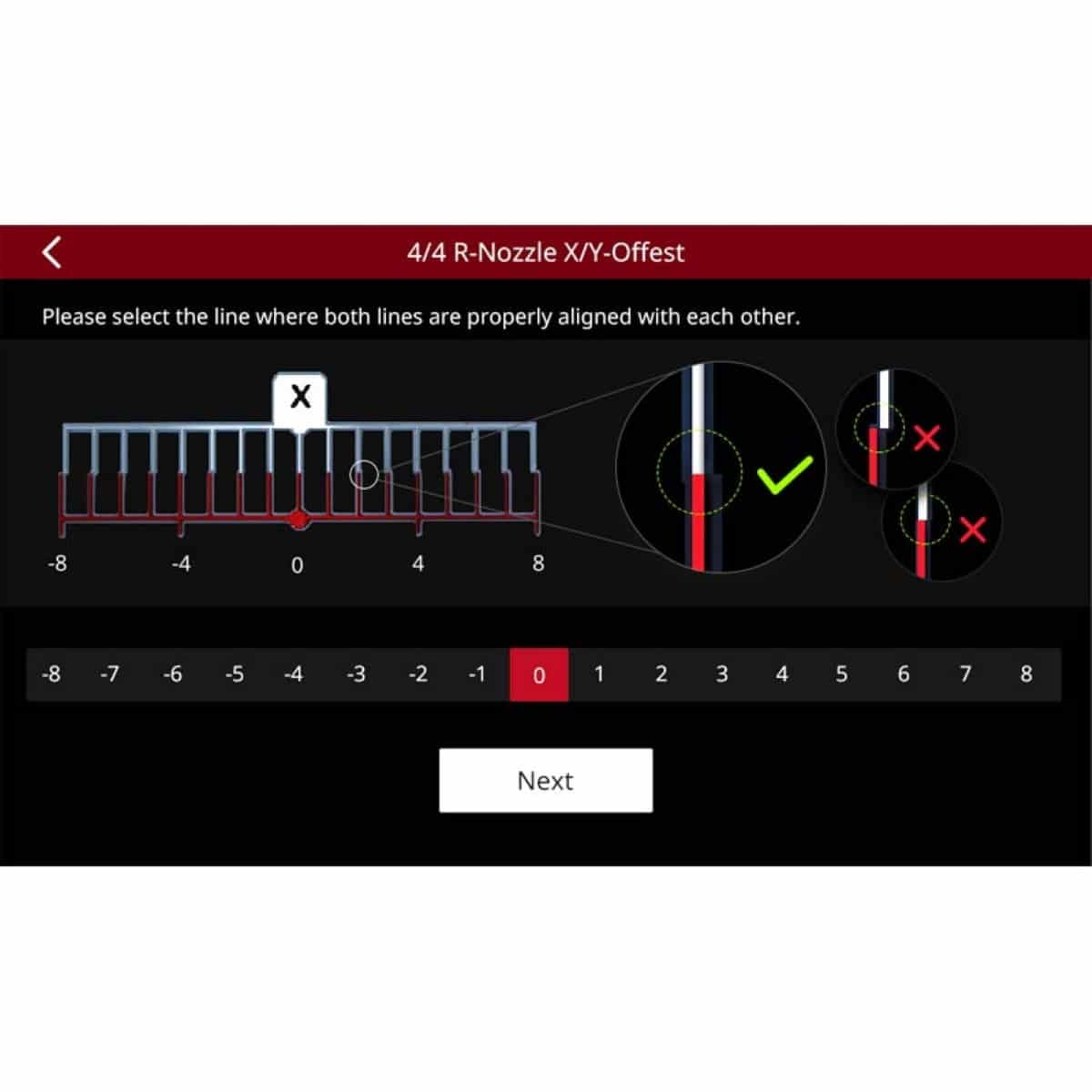

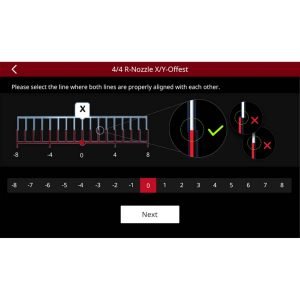

Assisted X/Y Offset Calibration

- Easy to use step-by-step video guide

- Enhances higher accuracy

- Saves time and lowers cost

Large Build Volume

- Up to 330 x 240 240 mm

- Large build volume for bigger prints

- More options for designs

Power Save mode

- Turns off the RaiseTouch and LED lights

- Saves energy while printing through the night

Safety Mode

- Detects whenever a door is opened and pauses the print

- Prevents damage to printing models

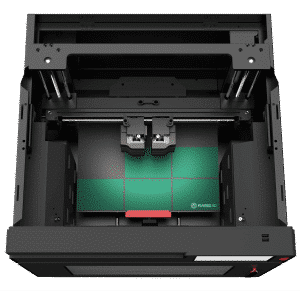

Flexible Build Plate

- Flexible build plate with BuildTak

- Easily remove prints

- Proven durability over 5,000 prints

Motion Board

- Designed to maximize advantages of IDEX technology

- Driven by Reprap firmware, and Duet electronics with Raise3D enhancements

Compatible with a Variety of Filaments up to 300℃

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Enforced / Carbon Fiber Enforces / Metal Particles Filled / Wood Filled

Intuitive User Experience

Visual Interface / Rapid Reviewing / Visual Print Progress / Full Adjustment Control

- 7-inch touch screen

- Integrated setting control

- On screen assistance

- Visual model selection

Never Lose a Print

- Second Generation Power Loss Resuming

- New Extruder wtih Filament Run-out Sensor

“I actually knocked off the power accidentally. I was currently doing a 96 hours print with only 2 hours left. As I raised my head to scream in terror, I turned the machine back on and it asked me to continue print. THIS WAS A LIFESAVER!” – Shon Robinson

HEPA Air Filtration

- Enviromentally friendly

- Designed to silently remove nano-particles

| General | |

| Build Volume (W×D×H) | Single Extruder Print: 13×9.4×9.4 inch / 330×240×240 mm Dual Extruder Print: 11.6×9.4×9.4 inch / 295×240×240 mm |

| Machine Size (W×D×H) | 23.9×23.5×18.3 inch / 607×596×465 mm |

| Print Technology | FFF |

| Motion System | Independent Dual Extruders |

| Filament Diameter | 1.75 mm |

| XYZ Step Size | 0.78125, 0.78125, 0.078125 micron |

| Print Head Travel Speed | 30 – 150 mm/s |

| Build Plate | Flexible Steel Plate with Buildtak |

| Max Build Plate Temperature | 110 ºC |

| Heated Bed Material | Silicone |

| Build Plate Leveling | Mesh-leveling with Flatness Detection |

| Supported Materials | PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber / Infused / Metal Fill / Wood Fill |

| Nozzle Diameter | 0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available) |

| Max Nozzle Temperature | 300 ºC |

| Connectivity | Wi-Fi, LAN, USB port, Live camera |

| Noise emission (Acoustic) | <50 dB(A) when building |

| Operating Ambient Temperature | 15-30 ºC, 10-90% RH non-condensing |

| Storage Temperature | -25℃ to +55℃, 10-90% RH non-condensing |

| Technical Certifications | CB, CE, FCC, RoHS |

| Filter | HEPA filter with activated charcoal |

| Electrical | |

| Power Supply Input | 100-240 V AC, 50/60 Hz 230 V @2 A |

| Power Supply Output | 24V DC, 350 W |

| Software | |

| Slicing Software | ideaMaker |

| Supported File Types | STL, OBJ, 3MF |

| Supported OS | WINDOWS/ macOS/ LINUX |

| Machine Code Type | GCODE |

| Printer Controller | |

| User Interface | 7-inch Touch Screen |

| Network | Wi-Fi, Ethernet |

| Resume Print after Power Outage | Firmware recording, no need for battery installation. Protection from any condition. |

| Screen Resolution | 1024*600 |

| Motion Controller | ARM Cortex M7.400MHZ FPU |

| Logic Controller | NXP ARM Cortex-A9 Quad 1 GHz1GB |

| Memory | 1GB |

| Onboard Flash | 8GB |

| OS | Embedded Linux |

| Ports | USB 2.0*2, Ethernet*1 |

Yderligere information

| Vægt | 42,7 kg |

|---|---|

| Build Volume | 295 × 240 × 240 mm, 330 × 240 × 240 mm |

| Producent | Raise3D |

| Extruders | 2 |

| Filament Diameter | 1.75 mm |

| Anbefalede Print hastighed | 30 – 150 mm/s |

| Type | FDM Printer |