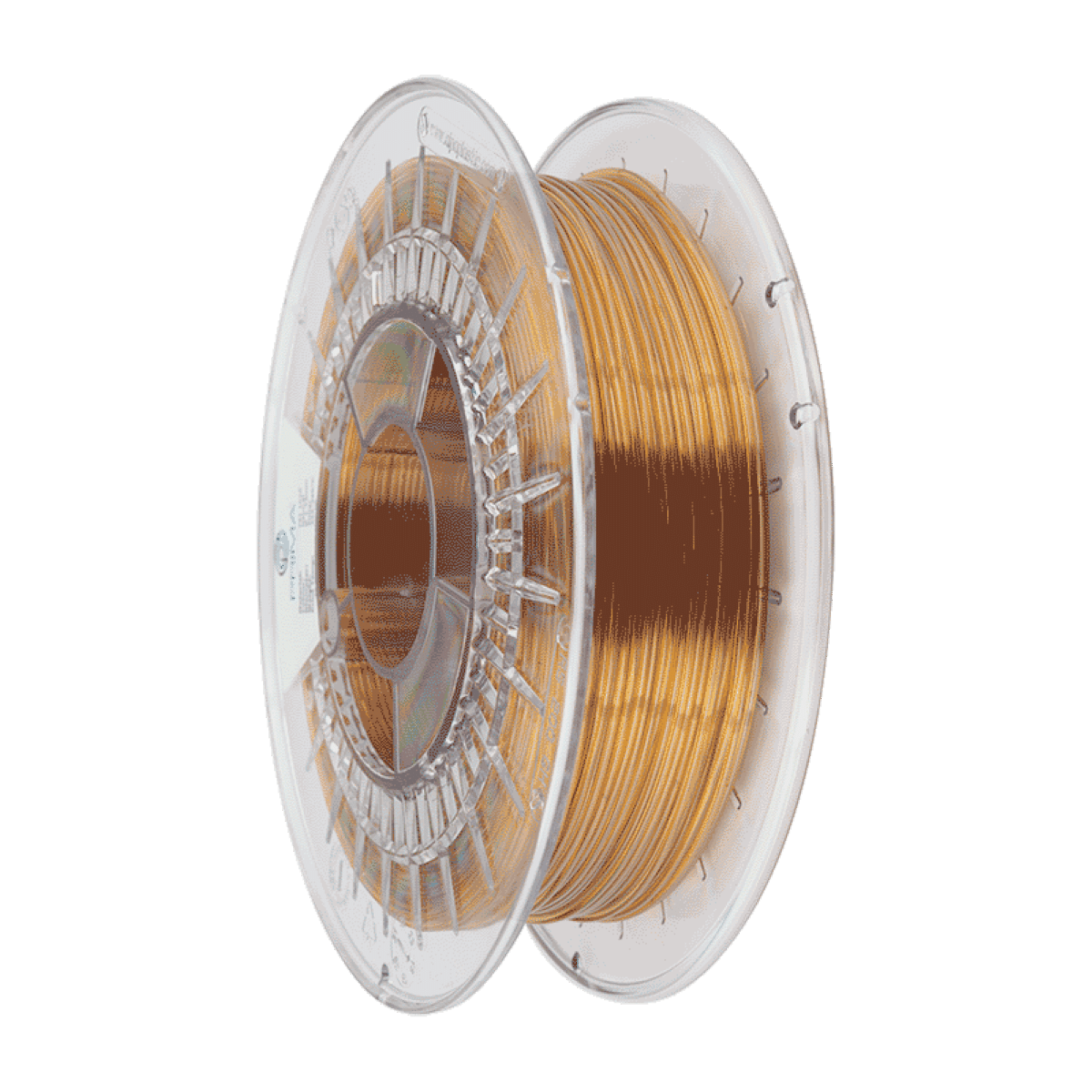

PrimaSelect PEI Ultem 1010 – 1.75mm – 500g – Natural

1.259,00 kr. incl. moms

På fjernlager, leveringstiden er 3 - 4 hverdage

Fragt fra 49,- fri fragt ved køb over 500,-

Beskrivelse

Polyether Imide (PEI) Ultem 1010 3D printer filament – Flame-retardant plastic UL94 V0 & 5VA ratings

PrimaSELECT Polyether Imide (PEI) Ultem 1010 is an amorphous, amber to transparent thermoplastics with a glass transition temperature (Tg) of 217 °C. The 3D printing material performs in continuous use up to 170 °C. This inherently flame-retardant plastic has UL94 V0 and 5VA ratings.

Material properties PrimaSELECT Ultem 1010:

- Polyether Imide (PEI) 3D printer filament

- Amorphous, amber to transparent thermoplastics

- Glass transition temperature (Tg) of 217 °C

- Performs in continuous use up to 170 °C

- Flame-retardant plastic – UL94 V0 and 5VA ratings

- Perfect for aerospace, automotive and electronics industry

PEI Filament – High manufacturing quality

The PrimaCreator PEI Filament has unique properties because it does not come into contact with water during the production process and is directly packaged in a vacuum packaging. These properties make the PrimaCreator PEI Filament particularly suitable for usage in FDM and FFF 3D printers. The material has an excellent adhesion between layers which results in great improvement of the impact resistance, strength, durability and the printing process.

To make a successful PEI print there are a few things to keep in mind

The printer must have the performance to meet the PEI filament and it should be printed with a nozzle temperature of 350-380°C. The heat bed should be set to 120-160°C and a heated chamber is important to have. It´s also very important to make sure that the printer is placed in a room where there´s hardly any draft and temperature fluctuations.PEEK is best printed on a PEI sheet at a printing speed of 15-30 mm/s.

| Basic Data | |

| Filament Typ | PEI Ultem 1010 |

| Diameter | 1,75 mm |

| Weight | 0,50 kg |

| Lenght | 164 m |

| Printing Parameter | |

| Recomended Printing Temp Min | 355 ºC |

| Recomended Printing Temp Max | 390 ºC |

| Recomended Printbed Temperature Min | 120 ºC |

| Recomended Printbed Temperature Max | 160 ºC |

| Recomended Printing Speed Min | 20 mm/s |

| Recommended Printing Speed Max | 35 mm/s |

| General | |

| Specific gravity | 1,27 g/cm3 ISO 1183 |

| Mold Shrinkage | 0,5 – 0,7% |

| Specific volume resistivity | 1.0E+15 Ω*cm IEC 60093 |

| Temperature | |

| Vicat softening temp | 215 °C ISO 306/A50 |

| Heat deflection temp | 200 °C ISO 75-2/Be |

| Tensile | |

| Tensile strength | 105 MPa ISO 527-2/50 |

| Tensile modulus | 3200 MPa ISO 572-2/1 |

| Elongation | |

| Elongation at yield | 6 % ISO 527-2/50 |

| Elongation at break | 60 % ISO 527-2/50 |

| Flexural | |

| Flexural Strenght | 160 % ISO 178 |

| Flexural Modulus | 3300 ISO 178 |

| Other | |

| Impact Strength | 5 KJ/m2 ISO 180-1A |

Yderligere information

| Brand | PrimaCreator |

|---|---|

| Anbefalede Print hastighed | 15 – 30 mm/s |

| Anbefalede Print Temperatur | 355 – 390 °C |

| Anbefalede Heated Bed Temperatur | 120-160 °C |

| Millimeter | 1.75mm |

| Farve | Natural |

| Type | Industrial, PEI |

| Vægt | 500 gr |