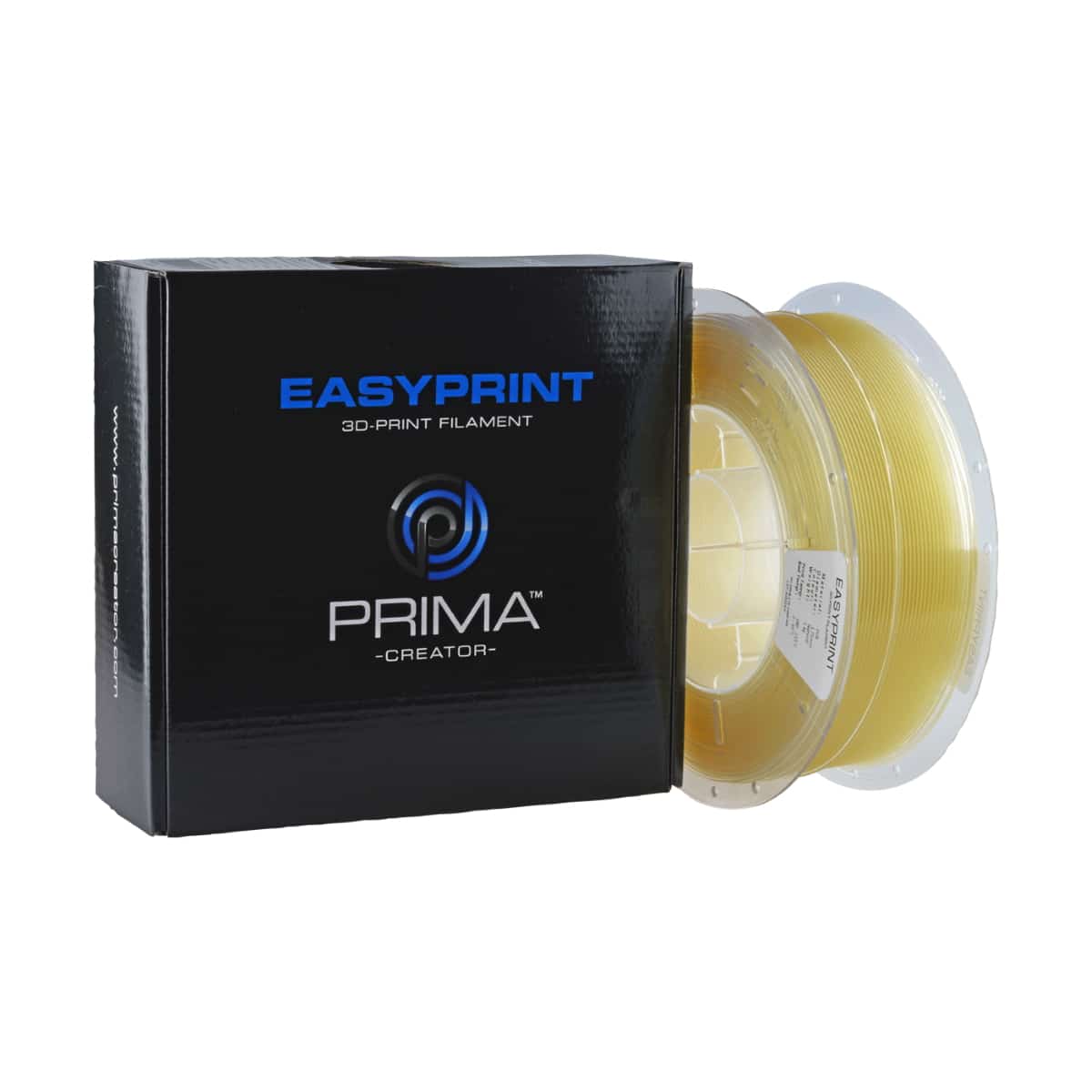

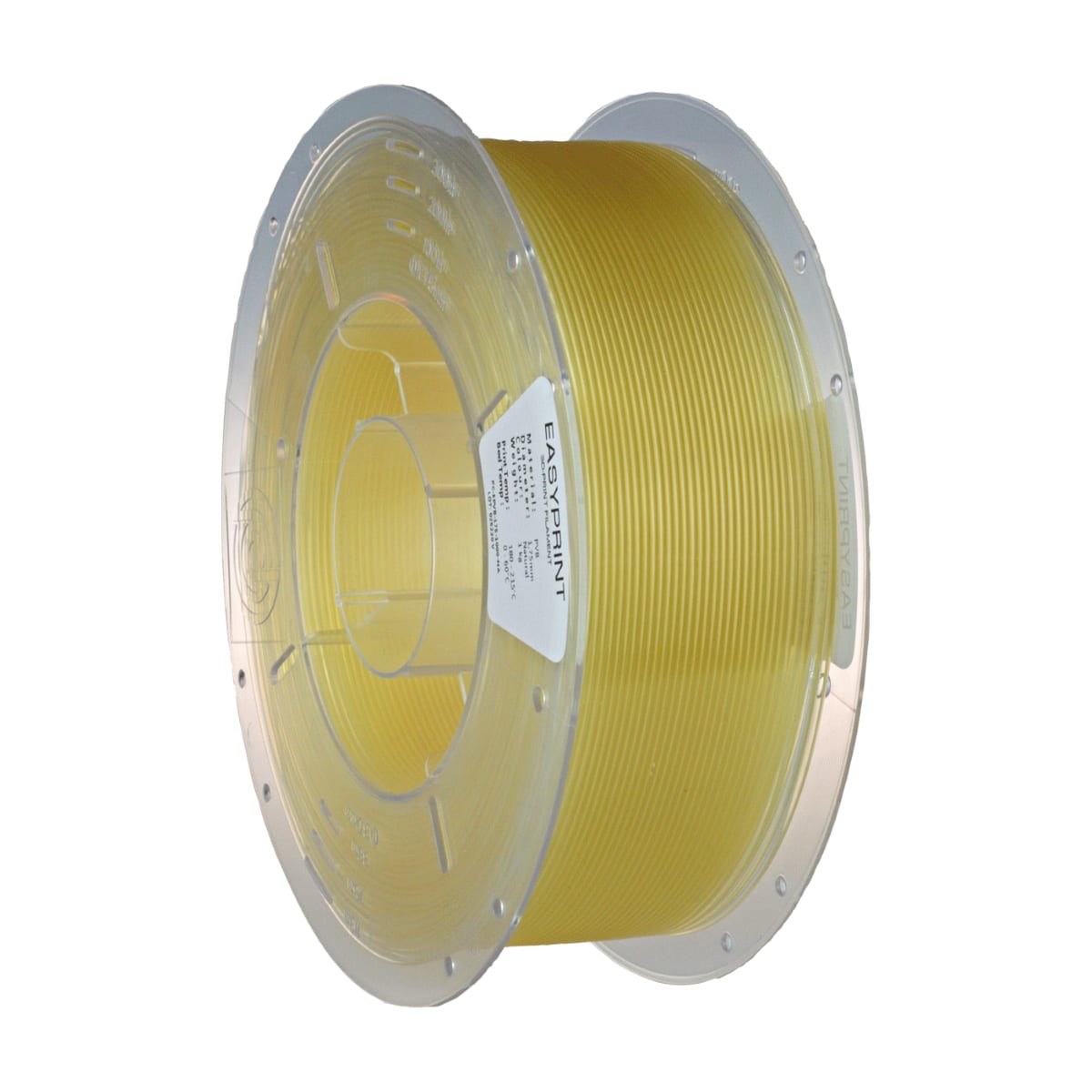

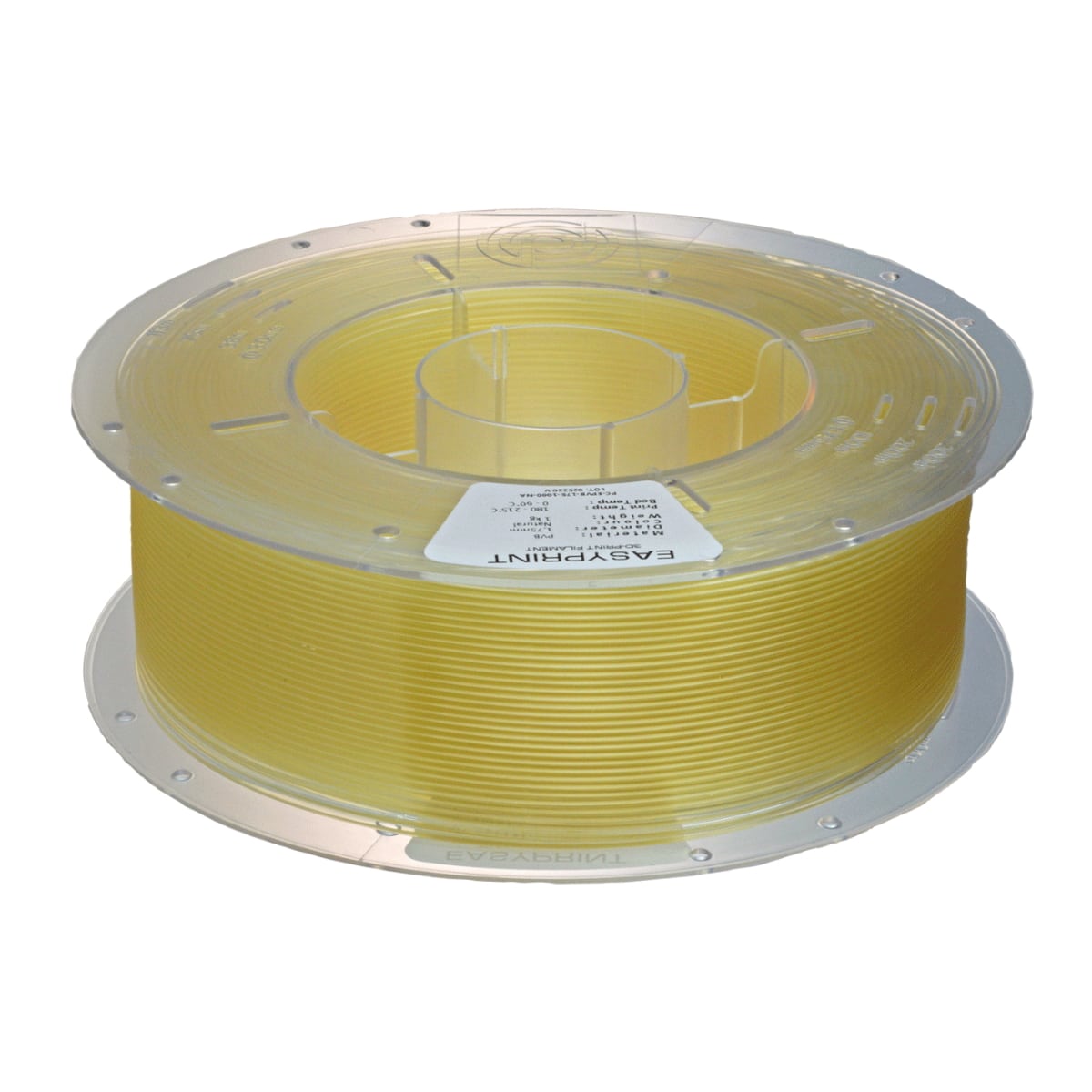

EasyPrint PVB – 1.75mm – 1 kg – Natural

400,00 kr. incl. moms

Ikke på lager

Fragt fra 49,- fri fragt ved køb over 500,-

Beskrivelse

PVB (PolyVinyl Butyral) is a new kind of filament that has some unique and attractive properties.

It has excellent layer bonding and the mechanical properties outperforms PLA. It has no odor or unpleasant smell and requires no heated bed (but recommended). PVB can be printed at fairly low temperatures (around 220) which means that it can be used in almost all printers on the market, including printers with a bowden set-up.

PVB is the first type of filament that is designed for post-processing and the removal of layer lines to achieve a very smooth surface. This is done with the help IPA (Isopropanol) and you can spray it or dip the whole print in it depending on the effect you are after. Once this is done you are left with a completely smooth surface.

Yderligere information

| Brand | PrimaCreator |

|---|---|

| Millimeter | 1.75mm |

| Farve | Natural |

| Type | PVB |

| Vægt | 1 Kg |