-

×

1 × 169,00 kr.

1 × 169,00 kr.

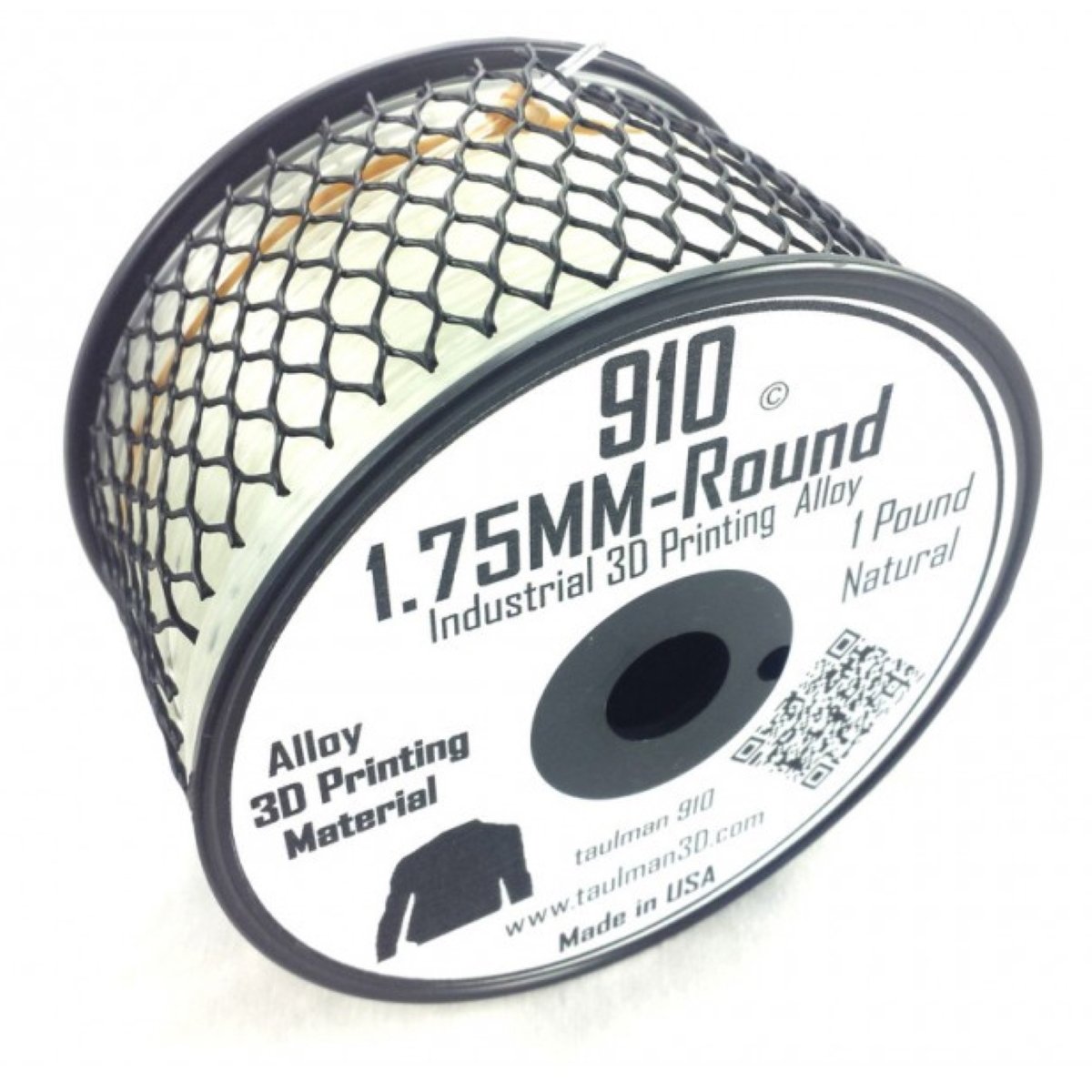

Taulman Alloy 910 – 1.75mm – 450g – Clear

325,00 kr. incl. moms

Ikke på lager

Fragt fra 49,- fri fragt ved køb over 500,-

Varenummer (SKU): 0688295584292

Kategorier: Filament, SPECIAL Filament

Beskrivelse

Alloy 910

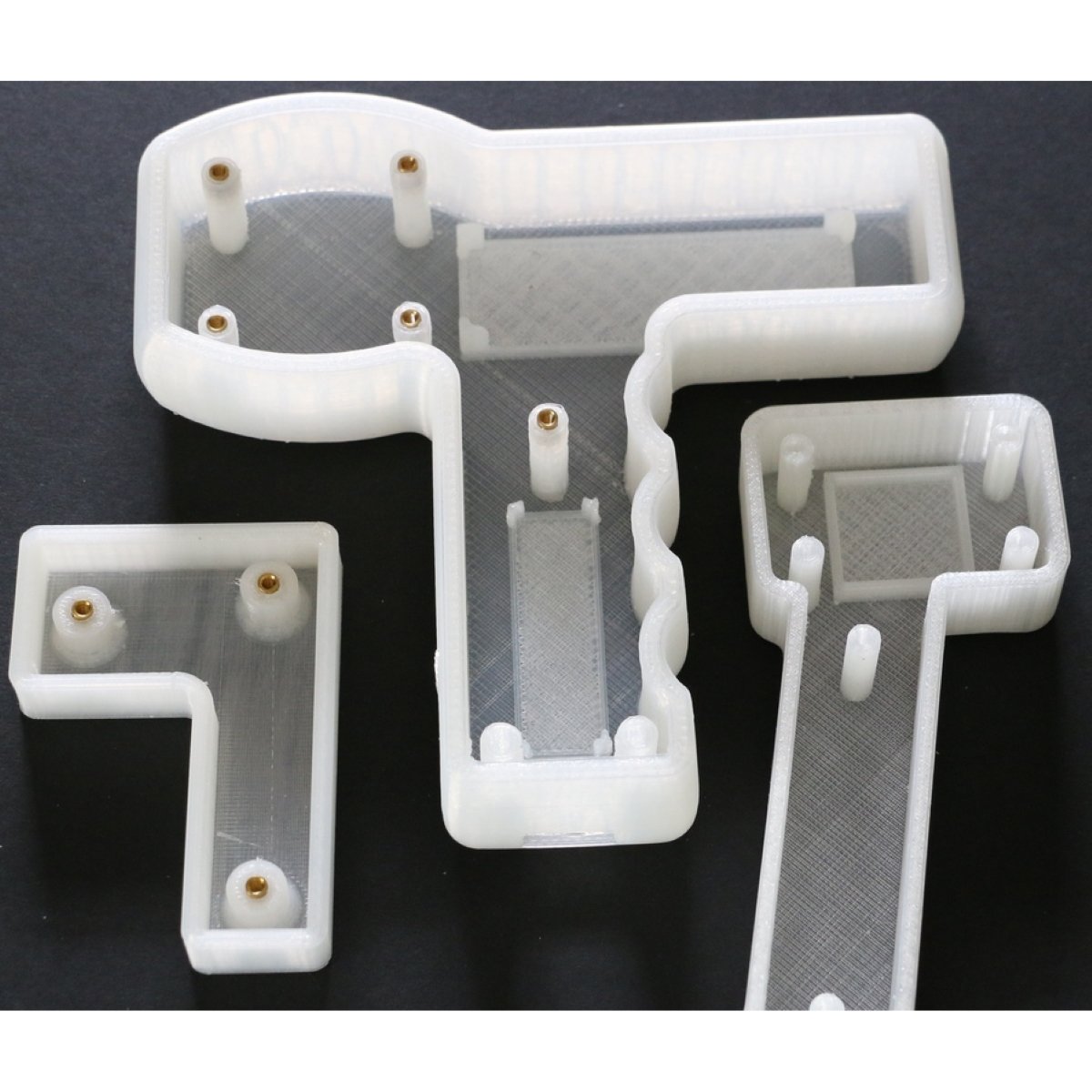

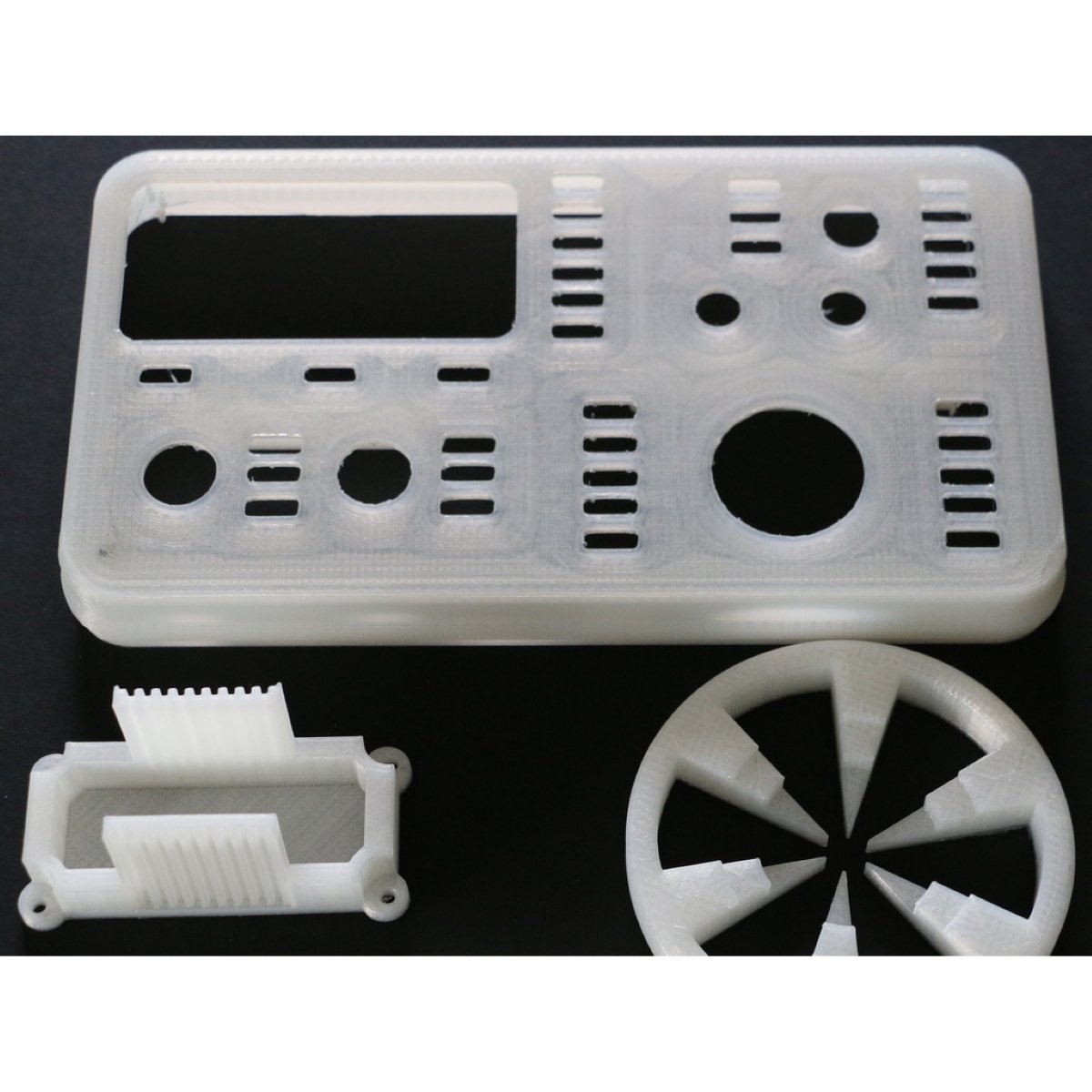

910 is the first 3D Printable High Impact, High Durability co-polymer Alloy with a tensile strength of 8,100PSI, thus matching 10-15%% glass filled materials! Alloy 910 is meant for high temperature high strength high durability uses. Alloy 910 is an excellent material for molding , Robotics, Machining or any need that requires a High Tensile feature along with high durability. Due to Alloy 910’s chemical composition, it has the least water absorption of all similar materials containing a Nylon component.

Specifications:

| Print temp | 245C – 250C |

| Nozzle | any size |

| Print speed | equivalent to ABS |

| Retraction | 1mm/.1mm nozzle or fop a .5mm nozzle = 5mm |

| Print bed | Cold = BuildTak with coat of PVA Hot = Glass heated to 45C with coat of PVA (PVA is 50% water and 50% “Elmers Glue All”) |

| Shrinkage | 0.0033 in/in |

| Tensile Strength | 8,100PSI |

| Modulus PSI | 72,932 |

| Max Elongation at break | 31% |

| Tg | 82C |

| Transmission | 75% |

| Color | Clear w/Subtle Amber – May be dyed with acid based dyes. |

Yderligere information

| Farve | Clear |

|---|---|

| Millimeter | 1.75mm |

| Type | Nylon |

| Brand | Taulman |

| Vægt | 450 gr |

Relaterede varer

Tilbud

Tilbud

Tilbud