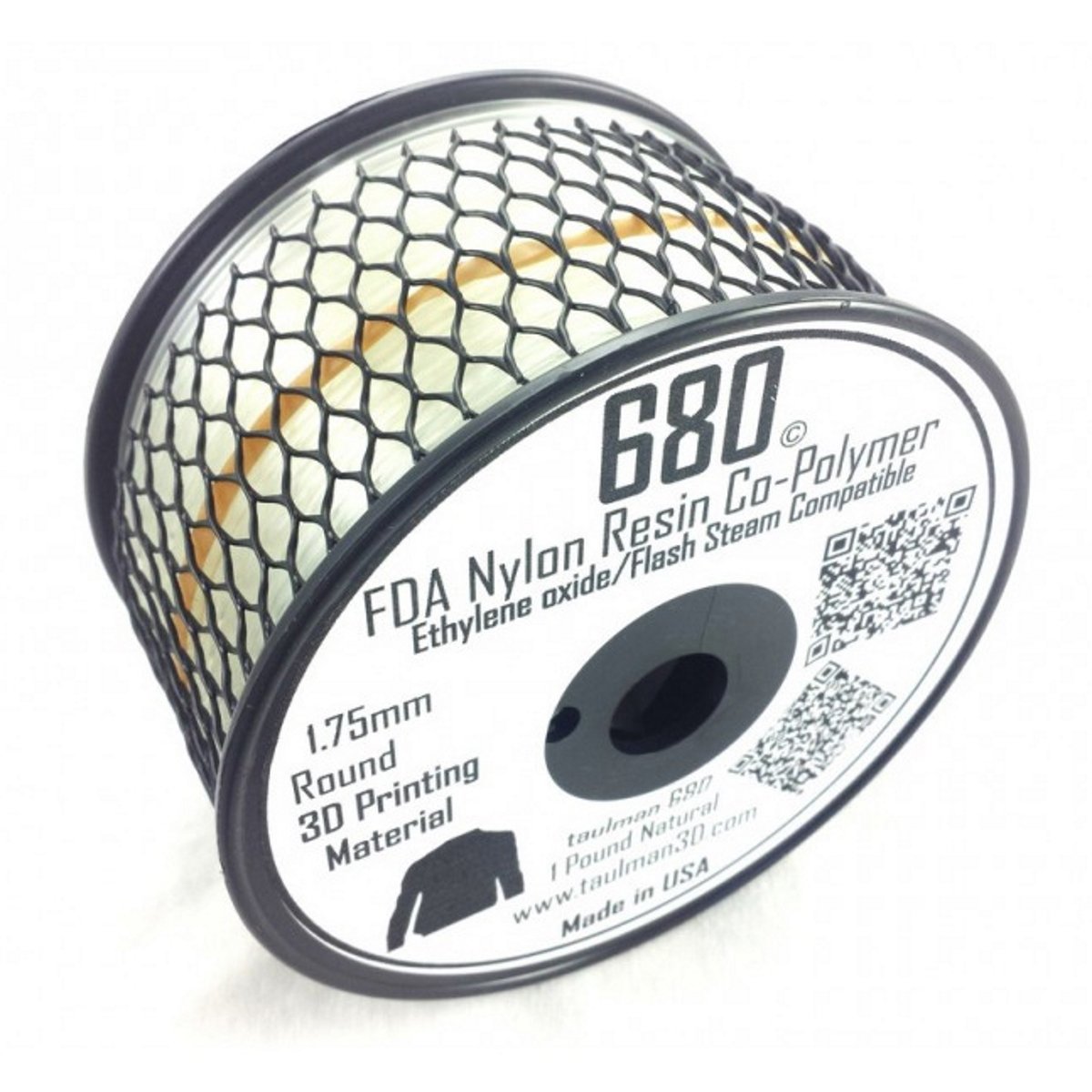

Taulman Nylon 680 – 1.75mm – 450g

525,00 kr. incl. moms

Ikke på lager

Fragt fra 49,- fri fragt ved køb over 500,-

Beskrivelse

Nylon 680, an innovative new nylon-based material for Fused Filament Fabrication (FFF) 3D printing, is designed for use in a wide range of industries, including: medical, dental, food processing, and robotics. Nylon 680 is compatible with sterilization procedures, has FDA approval for indirect food contact, and is designed to have superior strength and physical attributes when compared to consumer-grade materials currently on the market; 680’s specifications are highly desired by industry and hobbyists alike.

For Use by Medical, Dental, and Food Processing Industries

Sterilization Properties

Nylon 680 is compatible with the following sterilization methods, used globally in scientific laboratories for conducting a wide range of research:

Ethylene oxide sterilization compatible (Low temperature)

Steam/Boiling sterilization compatible (High temperature)

Sterilization is important for researchers becaus e it removes all fungus, bacteria, and other microbes which may be detrimental to the conditions of experimentation. Compatibility with sterilization processes is a rare material property in the 3D printing industry and is a unique attribute of Nylon 680.

Lab Applications include:

Scaffolds to grow cells

Tissue engineering

Prototyping medical devices and prosthetics

On-demand manufacturing of custom laboratory equipment

Under EU Consideration for Dental Applications

Dentists in the European Union are currently investigating this material for use in their practices; as such, it is currently under certification testing for an EU Dental CE marking, which would allow Nylon 680 to be used commercially in dentistry.

Food-Processing Applications

Nylon 680 is approved for used in food storage and handling; it can be used to make dishware, utensils, and food decorations where the alcohol percentage is less than 8%. It is also dishwasher safe.

Specifically, Nylon 680 is manufactured to meet FDA 21CFR177.1500. PART 177

“INDIRECT FOOD ADDITIVES” POLYMERS Subpart B–Substances for Use as Basic Components of Single and Repeated Use Food Contact Surfaces.

Vacuum Sealed and Traceable

Nylon 680 comes vacuum sealed and with a serial/batch number to allow traceability. This allows you to be sure your filament has the aforementioned properties.

Veterinary Use

Due to its unique properties, Nylon 680 is well-suited for use for veterinary application including casting animals and developing custom prosthetics.

Excellent material for high-strength, functional 3D printed parts

Stronger than PLA and ABS

Printed parts with Nylon 680 have been tested independently and are shown to be superior in strength when compared to other commercially available FFF 3D printing materials, and even to injection molded parts with PLA or ABS.

In laboratory testing, 3D printed samples of nylon 680 reached an average tensile modulus stress of 28,634 psi (197.42 MPa); in comparison, Nylon 645 reaches a tensile modulus of 27,141 psi (187.13 MPa).

Supports Non-Destructive Evaluation (Transparency)

Nylon 680 has approximately 20% opacity, making it considerably more transparent than Nylon 645. This is a major requirement for industry, as it supports “Non-Destructive Evaluation,” allowing users to confirm that their part printed properly.

Precision 3D Printing (Low Shrinkage)

Nylon 680 has very low shrinkage, allowing for printing parts with tight tolerances; this means users who are creating functional parts with a specific size requirement can be sure Nylon 680 is up to the task. Nylon 680 also maintains the well-known nylon slippery surface as requested by clinics and industry.

Superior Performance for Engineering

Nylon 680 is also intended to trail blaze the path for 3D printing in robotics. The robotics industry is currently developing new motors specifically designed to withstand high torque, with a minimal end-to-end shaft length. Motors with such designs will be the standard for articulated joints and will require non-standard gearing as well as interconnecting hubs and mating flanges. Nylon 680 is an attractive material to meet the aforementioned requirements, as it is a high strength material with proven low-friction surface properties.

Nylon 680 can be used to print the large parts necessary for creating drones and related robotics applications.

Other Applications:

In addition, Nylon 680 can be used to print a wide range of functional items, including: glasses and other outerwear, wearable gadgetry, art, sporting equipment, durable custom parts needed for construction projects, and much more!

Care and Handling:

While Taulman nylon filaments are designed to avoid problems caused by humidity, nylon materials still inherently absorb moisture, which can affect their printability when the materials are not properly cared for. Fortunately, absorption of moisture is completely reversible.

Tips for handling nylon:

- In summertime, keep nylons in a non-humid environment

- Avoid storing nylons in an environment like a basement, which tend to be humid

- Consider using a dehumidifier in your materials storage room

- Consider using silica gel packets to absorb moisture

But what can you do if your material has been in a humid environment and has absorbed moisture?

As stated above, absorption of moisture is completely reversible. Drying nylon materials before using them for printing will remove almost all of the water molecules. You may use a blow dryer for this, or some desiccant packets. Even if Taulman nylons are submerged in water for weeks at a time, the process of water absorption can still be completely reversed. So no worries and print on!

Nylon 680 Specifications:

Tensile Strength = 4,686PSI +

Modulus PSI =28,634

Max Elongation at break = 226%

Print Temperature = 250C – 255C

Nozzle size = Any

Shrinkage = 0.006 in/in

Transmission = ~70%

Color = Subtle translucent Shell White when printed solid – May be dyed with acid based dyes.

- Recommended Extruder Temperature: 245-250°Cli>

- Recommended Print Bed Temperature: 60-90°C

- Recommended Print Bed Surface: Glass heated to 45C with thin coat of PVA

- Recommended Print Speed: 20-30 mm/s

Yderligere information

| Farve | Natural |

|---|---|

| Millimeter | 1.75mm |

| Type | Nylon |

| Brand | Taulman |

| Vægt | 450 gr |